Vacuum Foam Gripper Calculation

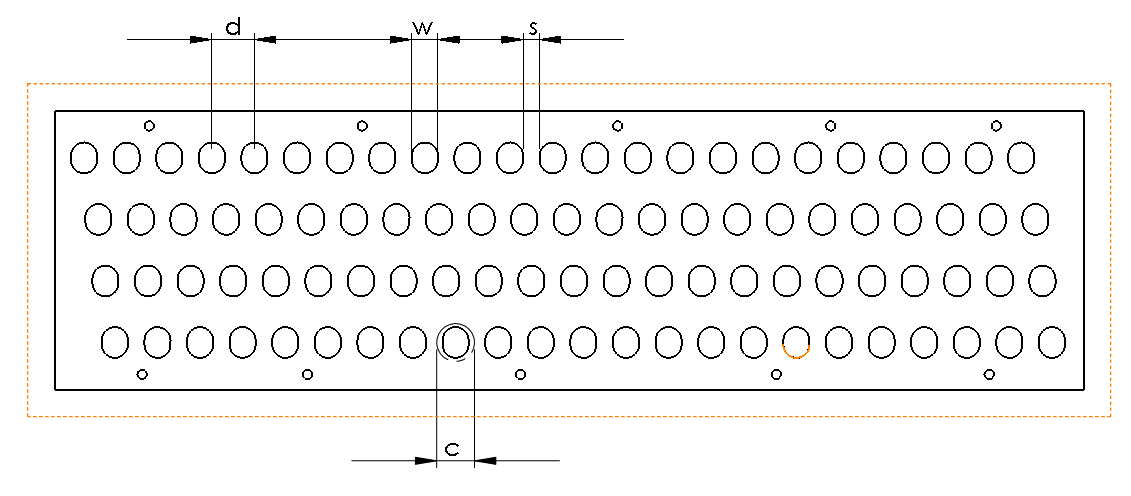

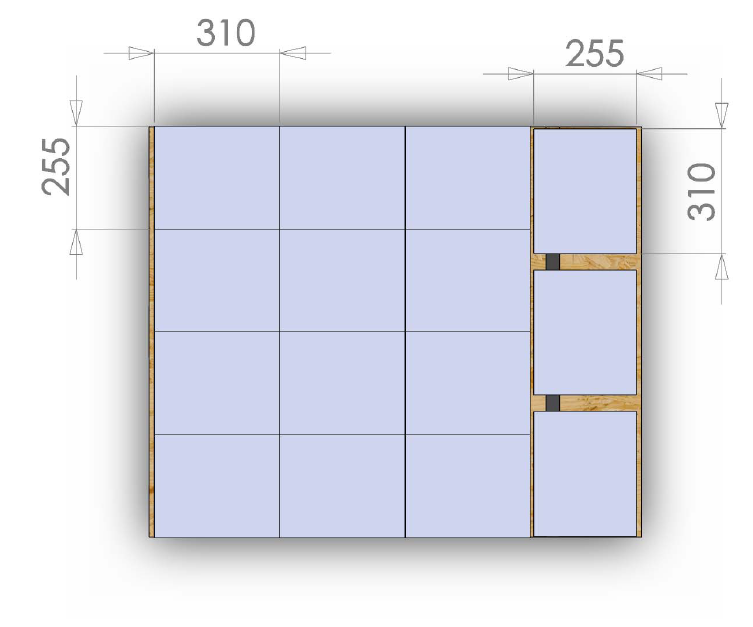

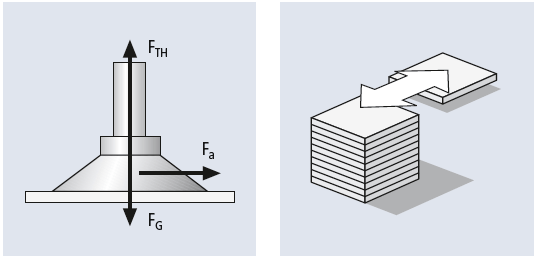

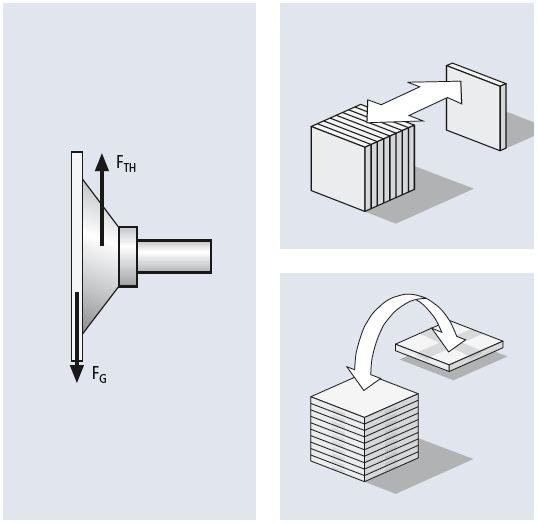

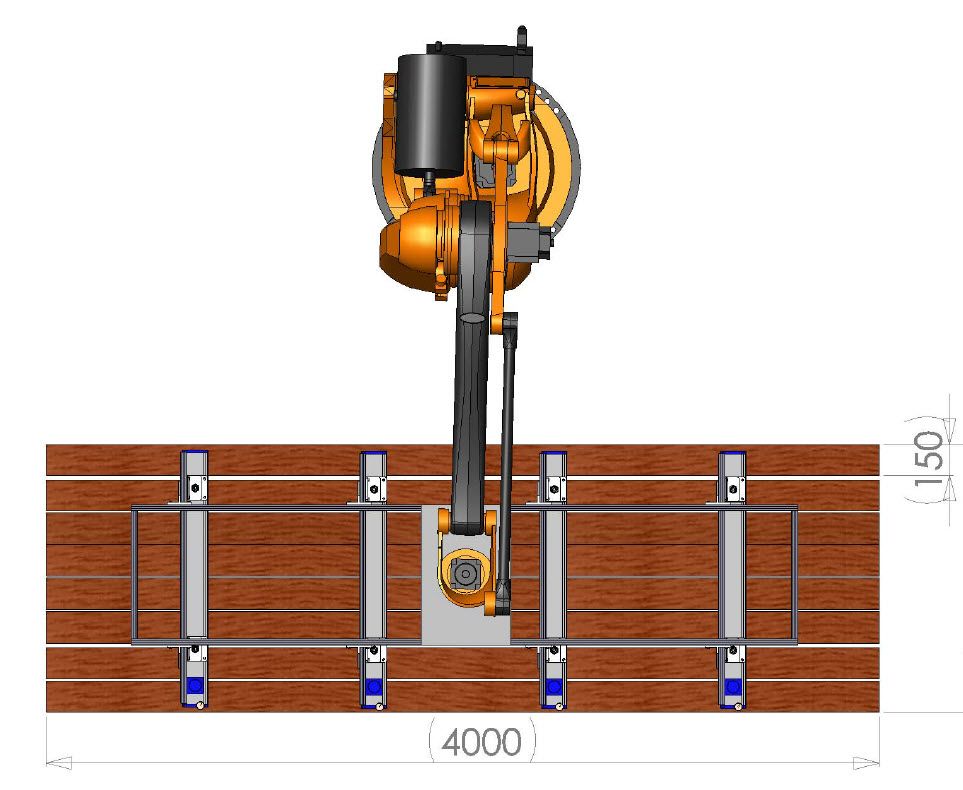

vacuum foam gripper calculation is important for how to know about foam pad cell force and how many vacuum foam gripper to use in vacuum handling system.

Sample Theoretical Force Calculation

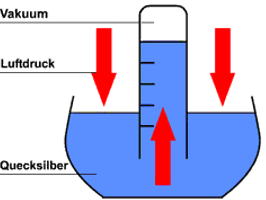

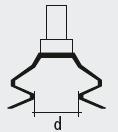

Vacuum level = -300 mbar

cell width = 11 mm

cell lenght = 13 mm

F = PA

= abs| – 300 / 100 | * 0.785 * ( 1.1 * 1.3 ) cm2

= 3.37 N/Cell

for online calculation click here...